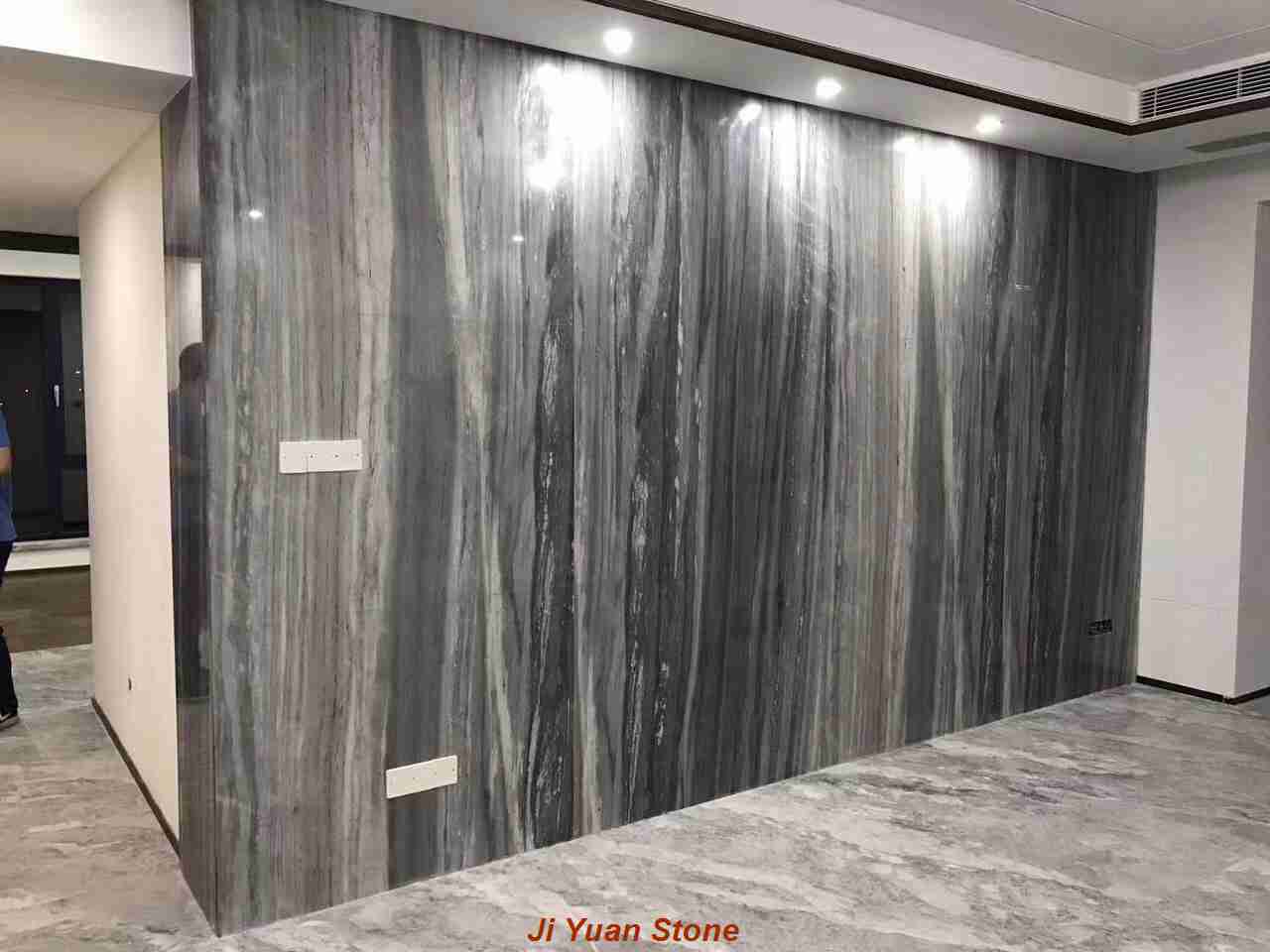

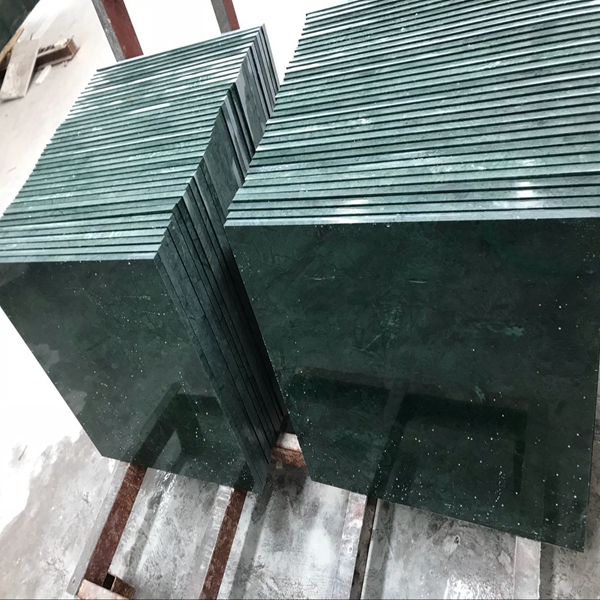

With the development of society and the improvement of living standards,people have higher requirements for the blue marble tile. The special process to treat the polished discount marble tile is fresh, natural,high-end atmosphere and durable.

First, what is the seamless treatment of blue marble tile?The so-called red marble tile seamless processing is to use a special process to process the seams of the stone paving to achieve a visually seamless effect.

Second, why do you want to do stone seamlessly?

1. The seamless treatment of stone can first enhance the overall sense of the stone floor, and can improve the overall decoration grade.

2. If it is not handled seamlessly, the gap between the plates will become a place for dirt and dirt in daily use. Daily clean water will stay in the gap, and together with various sources of pollution, it will cause problems such as stone pollution and stone lesions.

Third, the stone seamless processing operation process

1. Finished product protection:

Professional protection of wood solid surface, paint surface, wallpaper, wall covering, etc. with protective film (with static electricity).

2, cleaning and slitting:

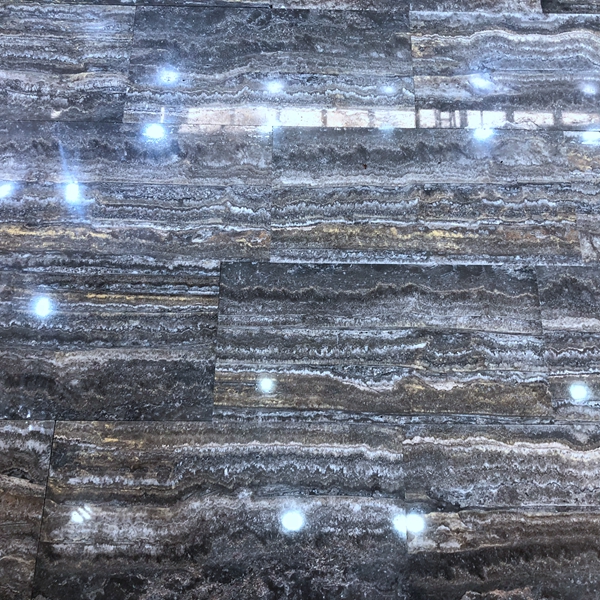

The original filler between the stone gaps is cleaned up, first clean the original filler between the stone gaps, and then use the special stone slitting machine to re-align the slits in the original stone installation, so that the gap between the stones is poor. Minimize and fill it with marble glue close to the stone color.

3, adjust the glue:

Use marble glue close to the color of the stone itself and perfectly color the marble glue to make it close to the original stone color to improve the overall sense and achieve the most ideal visual effect.

4, glue:

4, glue:

Filling the prepared marble glue, because the marble glue will completely shrink after a certain degree of shrinkage, so the marble glue should be slightly higher than the stone level, so that it will not be filled multiple times.

5, cut and polished:

Polished and polished fillers are used to make the discount marble tile a horizontal surface, increase the overall sense of the blue marble tile, and solve the problem of high and low gaps between the gaps to prevent the gap from returning to black again. Use a granite refurbished machine with a special cut-out abrasive piece to carefully polish the cut position to make it a flat whole with the red marble tile.

6, grinding and polishing:

Using a special granite polishing machine, the stone is ground from 50-3000 stone water-grinding pieces from coarse to fine, which makes the ground bright and new.

Fourth, seamless national quality standards:

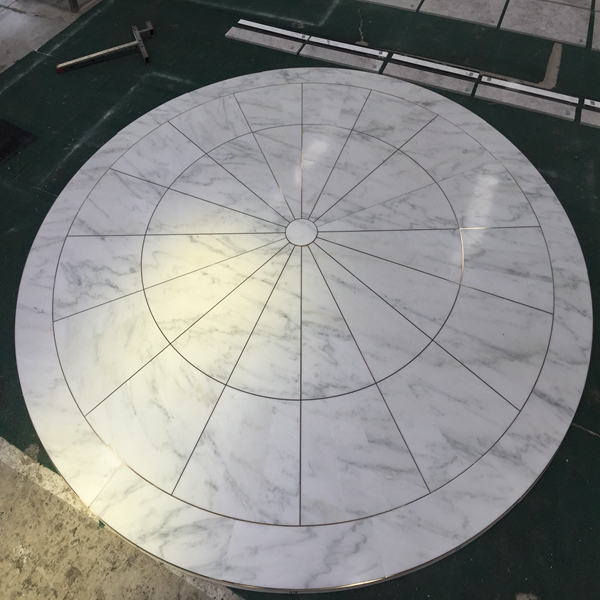

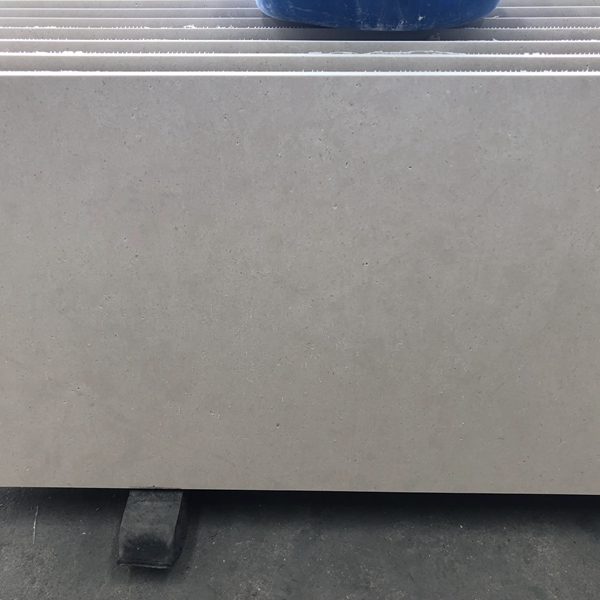

1 No half seam, broken seam, black seam, no shadow on both sides of the seam, the overall effect is 2 meters visually seamless.

2 The color of the gum and the stone have no obvious color difference, and the seam connection is natural and perfect;

3 water knife and parquet stitching lines are natural and smooth, no color mixing.

4 There is no obvious color difference, no ribbon, and the repaired area is consistent with the slab of the large plate.

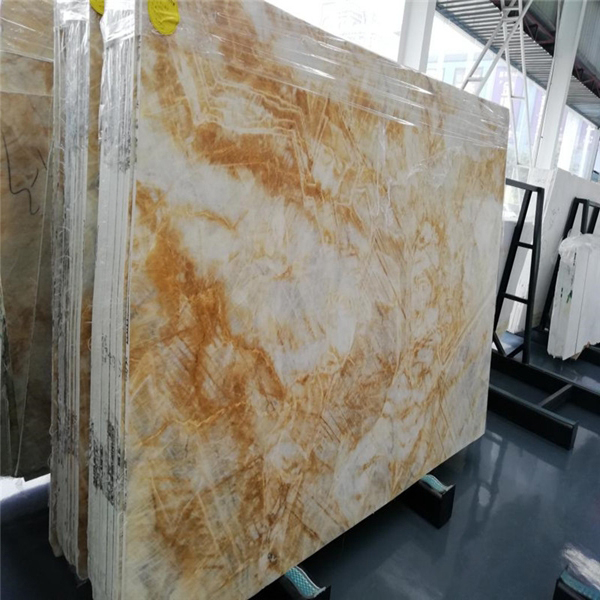

Fifth, the choice of materials:

In order to ensure the effect of seamless processing, different materials must be selected according to the requirements of the owner. The bonding performance, flexibility, easy-to-adjustability, polishing performance after polishing, shrinkage performance, anti-aging color change ability, etc. must all be considered. The material with strong adhesion is not easy to fall off the edge in the future; the material with high polishing property is easy to be polished after polishing, and the whole stone surface is not divided when the crystal surface is finished; the material with low shrinkage is not easy to collapse in the future; the anti-aging color change ability Strong materials are not easy to change color in the future.

Six, note:

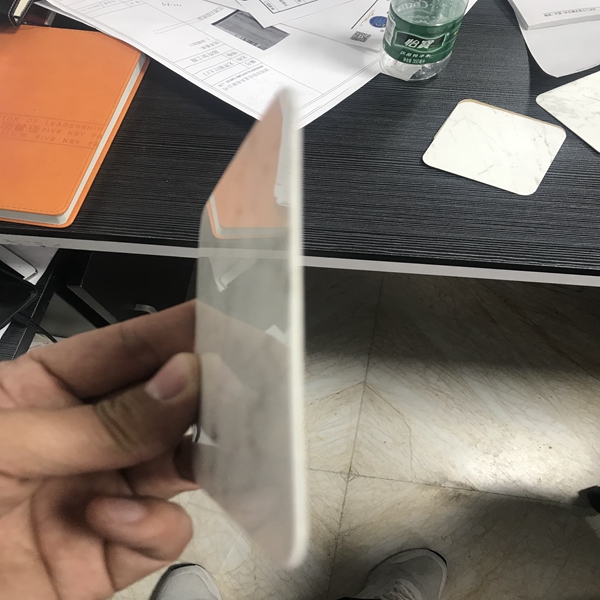

1. The slitting should not be too large, and the thickness of the opening sheet should not exceed 0.3, otherwise it is difficult to achieve the seamless effect of international regulations.

2. After slitting with the cutting piece, the marble and granite must be cleaned with both sides of the seam with a new art blade, otherwise the black seam will appear after the construction.

3, the ratio of seamless glue and curing agent must be moderate, and the modulation is uniform, otherwise, the seamless glue will not dry, and the construction will show a half seam.

4. When filling the seamless glue, it can only be pulled back once. When it returns to the pull, it will appear as a half seam due to the shrinkage of the seamless glue after drying and solidification.

4. When filling the seamless glue, it can only be pulled back once. When it returns to the pull, it will appear as a half seam due to the shrinkage of the seamless glue after drying and solidification.

5. Care must be taken when making seamless filling. In the seams of different hue stones, it must be "just right", not more, not less, otherwise, the construction will leave defects!

6. When seamlessly filling, the color of the gum must be dominated by dark stone. Otherwise, the seamless effect defect may be caused by the difficulty in modulating the light-colored colloidal hue.

7, special stone (Ariston white, volakas white, Calaeatta,Arabescato, Sevec White; wood fossil, wood stone and other soft stone; jade; quartz stone; microcrystalline stone,red marble tile etc.) must be painted before seamless filling Brush the corresponding discount marble tile anti-fouling agent, otherwise the oily substance in the gel will penetrate into the two sides of the blue marble tile slit, resulting in the end of construction and the gray shadow of the slit.

8. Quartz stone and microcrystalline stone can not be opened with inferior cutting piece with high brightness. Otherwise, the shadow will appear at the end of construction.