Dry pink and white marble grinding,as the name implies,does not add water when grinding faux marble floor.Adding water when grinding is called water grinding.What is the difference between the two? When is the dry grinding? When is the water mill?

1. What is the difference between uses of marble dry grinding and water grinding?

1, different grinding

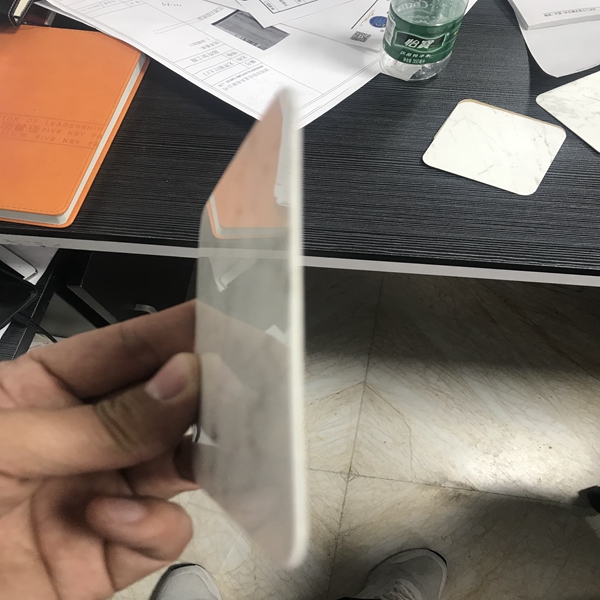

Most of the mainstream grinding tablets currently on the market are made of synthetic diamond particles and resin binders. Diamond is the diamond we usually say, and resin, in a broad sense, is a general term for a variety of high molecular polymers that can be used as plastic raw materials.

When the marble design is ground, the grinding piece and the surface of the dark gray marble tile are rubbed, and the high temperature is instantaneously generated under the speed and pressure of the machine rotation. This temperature can melt the general resin, and the inferior grinding piece is easily deformed and twisted when grinding, which is because of this reason.

Adding water to the natural marble stone water mill can accelerate the heat dissipation, and the requirements for the composition of the grinding sheet are slightly lower, while the dry grinding does not add water, and the heat is dissipated slowly. Therefore, the resin used for the dry grinding sheet must be selected from high-quality resin with high temperature resistance.

Simply put: due to the composition of the components, dry grinding tablets can be ground, ordinary water-grinding tablets can not be dry grinding for a long time, using high-quality resin grinding, dry grinding or water grinding.

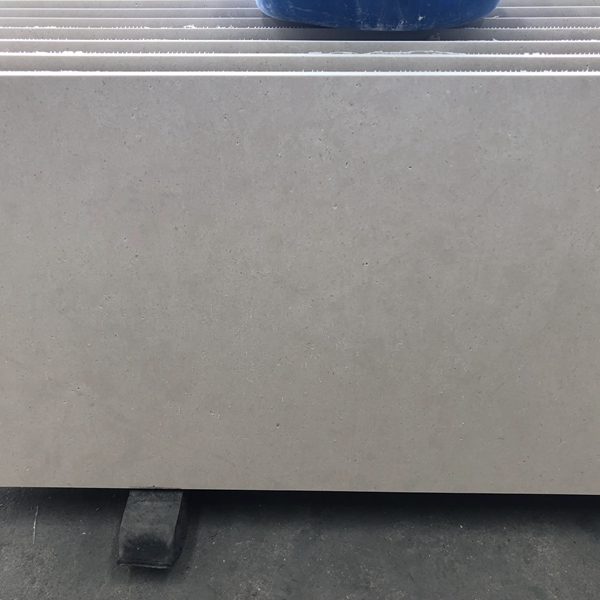

2, water mill damage to the white grey marble tile is less

The high temperature generated during the grinding of the marble floor tiles price can cause certain damage to the structural crystal of the buy marble flooring. turkish marble tile are burnt at high temperatures, which are prone to a series of problems such as loss of light, chipping, and chalking.

The reason is the composition of the marble white floor tiles. The main component of the marble is calcium carbonate. Calcium carbonate is converted into calcium oxide after being calcined at a high temperature, which is the so-called firing process of lime.

Chemical reaction formula: CaCO3 (heating) = CaO + CO2 (gas)

Adding water to the pink and white marble during grinding can accelerate the emission of heat and reduce the damage to the uses of marble.

3, the gloss of the water mill is more soft and beautiful

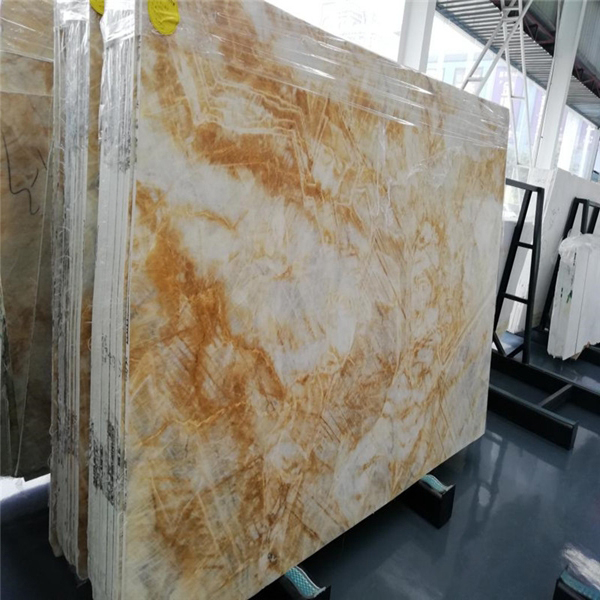

During the grinding and polishing process of the faux marble floor, all the light emitted by the high temperature is different from the light thrown out at the natural temperature.

The luster that is thrown out at natural temperature looks bright and bright, and under high temperature conditions, the heat generated by the friction moment has a certain destructive effect on the crystal structure of the grey and white marble floor tiles, so the gloss produced by the dry grinding has glare and burning. Eclipse, dry, not transparent.

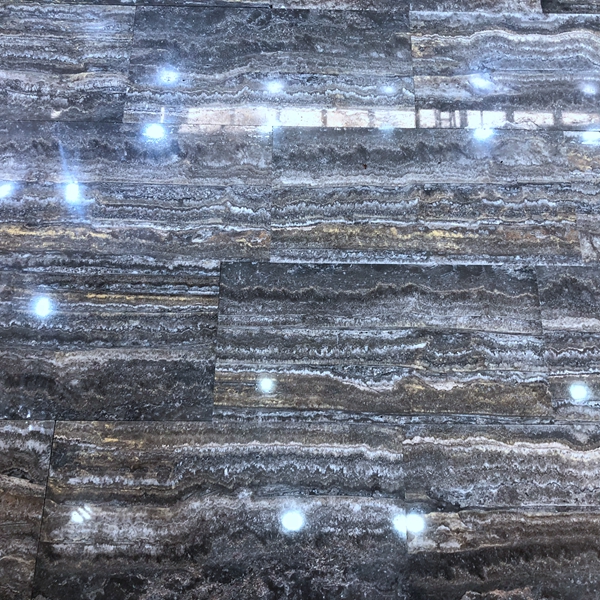

Generally, when black stone is ground, it tends to be white, and water mill is better than dry mill. The beige stone is dry-grinded all the way, and the color is not transparent, the bright is bright, but the gloss is dry and faint, which is due to the high temperature ablation during grinding.

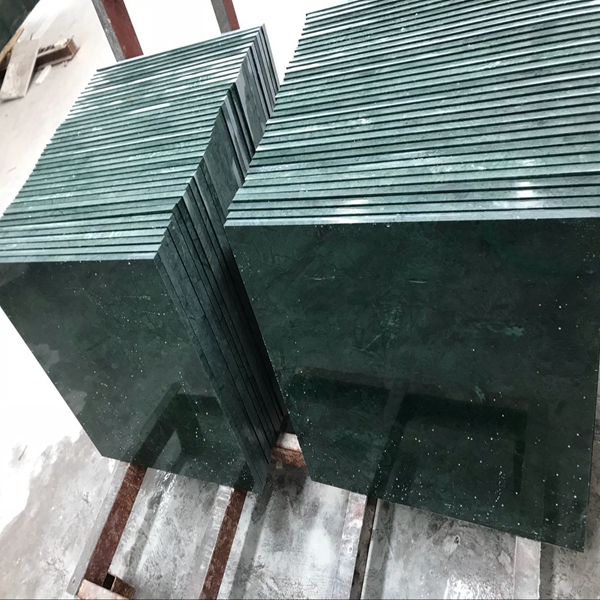

The heat generated by dry grinding is harmful to any big marble tiles. It is not obvious on white or beige light stone, but it is especially noticeable on black stone. Therefore, dark stone, relatively transparent jade, etc., it is best to grind.

4, the pollution caused by dry grinding is difficult to handle

Dry grinding produces dust, which is mostly flying in the air, and a small amount is dissolved or absorbed into the holes of the marble flooring price. These extremely fine dark grey marble tile powders enter the interior of the brown marble floor tile to absorb moisture and absorb moisture, which will pollute the pink marble flooring for a long time.

Flying dust in the air is very detrimental to the health of real marble tiles caregivers. Moreover, the dust generated during dry grinding is difficult to handle. The dust generated during the grinding process of the faux marble floor is very delicate and can produce a floating effect. As the mesh size increases, the fineness of the dust increases exponentially, and the dust volume becomes larger and larger. It is very difficult for you to deal with these dusts in the city.

In order to solve the problem of dust during dry grinding of uses of marble,in June 2016,Ji Yuan Stone developed a multi-function grinding and polishing system for pink and white marble, and introduced a new generation of portable polishing machine and dust cover.Use a JY dust cover with a pump to reduce 99.99% of the abrasive dust in the air.